Popping Sound When Turning Steering Wheel At low Speed – How To Fix?

A steering wheel is a crucial part of a vehicle as it is used to control its direction. Several parts make the steering wheel, including the steering shaft, tie rod, and control arms.

When these parts begin to fail, drivers notice various symptoms, including popping sound when turning steering wheel at slow speed. Since there are multiple parts, it may be hard to tell the failing part without diagnosing it fully.

Read on for a list of possible causes of the popping sound and the possible solutions you can try.

Popping Sound When Turning Steering Wheel at Slow Speed – 4 Reasons To Check

Worn-out ball joints and tie rod ends are among the causes of popping sounds when turning at low speed. However, the suspension joints may also wear out, causing contact and noises at the connection points.

The following list provides an overview of the possible causes of the popping sound when turning the steering wheel.

- Worn out ball joints, which the solutions include lubricating the ball joints and replacing them

- Failing Tie rod ends, fixed by applying lubrication on them.

- Problems with the lower control arm, mostly its bushings or the torque belts

- Worn-out suspension joints which need replacing

The following sections cover the causes and solutions in detail to help you understand better.

Related Post: Grinding Noise From Starter:

Worn-out Ball Joints

Ball joints are crucial when steering the vehicle as they ensure the knuckles move freely. Some vehicles may have two ball joints, a load bearing, and a follower ball joint.

The ball joints rely heavily on lubrication to work smoothly. Lack or low lubrication may cause these parts to make popping noises when the vehicle turns.

Solution:

Lubricate the ball stud and the socket in the ball joint to fix the problem. If these parts are already worn out, you may have to replace the ball joint. Depending on your vehicle’s type, replacing a ball joint may cost between $100 and $250.

Failing Tie Rod End

Tie rods transmit the turning input from the driver to the wheels allowing the vehicle to turn. The ends of the rod and the tie rod ends connect to the front wheels and the steering gear.

These ends contain ball joints, which like most joints, depend on grease for lubrication and to remain functional. The lubrication is lost over years of use, while dust and debris affect its effectiveness.

Solution:

Replace a defective tie rod end for better chances of success. However, if you suspect low lubrication, you can use a grease gun needle attachment to top it up.

Related Post: 7 Main Causes For Coolant Pouring Out Of Bottom Of Car!

Lower Control Arm Problems

The control arm also plays a key role in maintaining the vehicle’s stability. In most vehicles, there are two control arms, the upper connected to the steering knuckle and the lower connected to the ball joint.

Thus, the lower ball joint contains bushings known to wear out with time. Also, if the vehicle was serviced shortly before the problems, the bolts to either arm may be incorrectly torqued. When the control arms have problems, you will hear popping noises every time you turn the vehicle or hit a bump.

Solution:

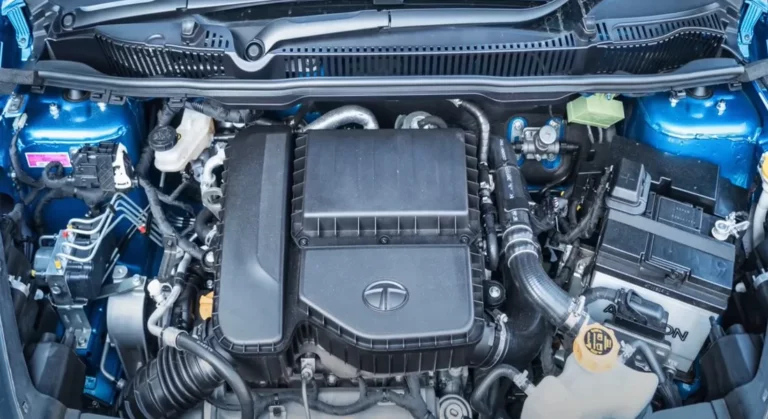

Ensure the bolts in the following image on the arms get the correct torque, which is 58-86 ft. lbs. in most cars. If the bushings are worn out or loose, tighten or replace them. The replacement cost can range between $250 and $350, labor cost included.

Worn-out Suspension Joints

The suspension joint absorbs vibrations from the wheels as the vehicle moves and allows the suspension arm to pivot. However, the vehicle may have multiple suspension arms which need regular servicing to avoid faults.

When nearing the end of their service time, the joints are too worn out that they make noises at the connection points. The vehicle’s handling may also deteriorate until the suspension joints get replaced.

Solution:

In most vehicles, the suspension joints should last over 100,000 miles, after which they should be replaced. Depending on the vehicle, ball joints should range between $50 and $200 to buy.

Diagnosing popping noise when turning at low speed

Though you now know the possible causes of the popping sound now, you still don’t know how to tell the specific part. Observing the wheels while they turn is one way to learn the noise source.

You can observe and diagnose the car by following the steps below:

- Step 1: Jack up the car

- Step 2: Have someone turn the steering wheel towards the right and then left

- Step 3: Watch and listen from below, taking note of all the parts making noises

With this diagnosis, you can tell the source of the noise. In case you have no one to help in the observation, you can use an engine stethoscope to learn the possible sound sources.

The downside is that the vehicle may only make noises when its weight is on the wheels. In this case, take the car to the mechanic to observe through an inspection pit.

Other ways to diagnose the problem include;

- Observe for loose or cracked bushings

- Apply suitable grease (our pick) to the ball joints and check if the sounds seize

- Check the suspension joints

popping noise when turning steering wheel – (FAQs)

The following section covers some frequently asked questions about the popping sound when turning at a slow speed.

1. Can I Drive a Car Which Makes a Popping Sound when Turning?

Yes, you can drive a vehicle that makes popping sounds when turning, but not for long. The popping noises are symptoms of a failing part that needs immediate checking and fixing.

2. What is The Cost of Repairing a Car Which Makes a Popping Sound When Turning?

The repair cost of the car with this problem ranges between $100 and $450. However, the repair shop, the cause of the sound, and the location are several factors that affect the price.

Bottom Line

Any noise, especially related to the steering wheel, is enough to cause worries in any driver. Most times, the noises symptomize a failing part that requires servicing or replacing. The article covers several of the possible causes and their solutions.

You may need to observe physically to be sure of the part causing the popping sound. While you can diagnose and fix these problems, you may need aid from a professional mechanic. However, ensure your car is regularly serviced to spot and diagnose the problems as soon as possible.

Related Posts: